Granulation

Purpose: Granulation (food, pharmaceutical)

Applicable equipment: Cylinder Granulator

Material: SUS316L

Improved processing capacity and durability of the screen.

Cylinder Granulator that achieves finer granulation.

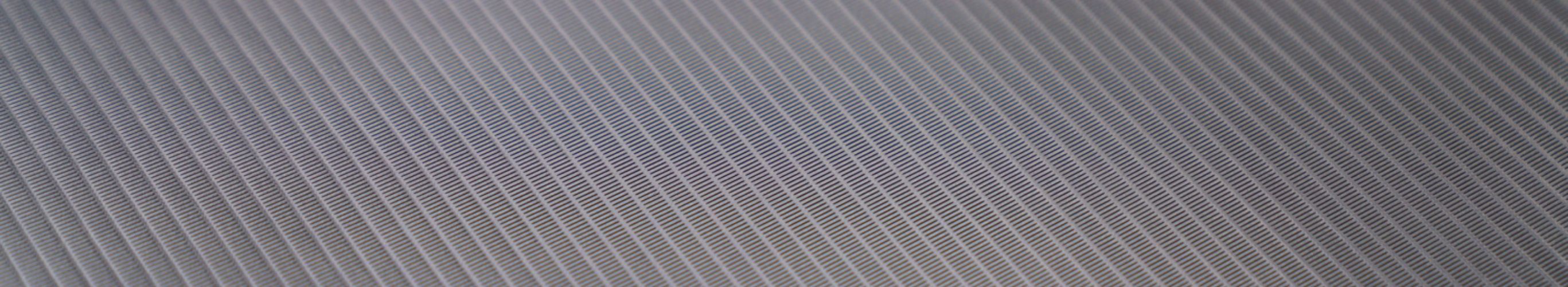

A cylindrical granulator has a unique blade agitation system that is suitable for wet granulation of all kinds of powders. Screens installed in cylinders are conventionally perforated with a punching method.

However, with this method, since it is necessary to reduce the thickness of the plate in order to make the hole diameter smaller, there is a limit to the size of the holes due to durability issue. So when granulating pharmaceutical or food granules, the life of the screen is very short (one week to one month), and the cost and labor of replacing it is a major burden making this method very questionable.

Our electron beam drilled screen has solved these problems at once. Since our technology can drill fine holes in thick-walled materials, service life is extended while labor, replacement cost and maintenance are reduced.

The separation efficiency has also been dramatically improved, making it possible to meet the growing need in recent years for reducing the size of granules.