Hole processing specifications / Size of processed goods / Purpose

Purpose

| Purpose | Applicable equipment | Product name | Field of application |

|---|---|---|---|

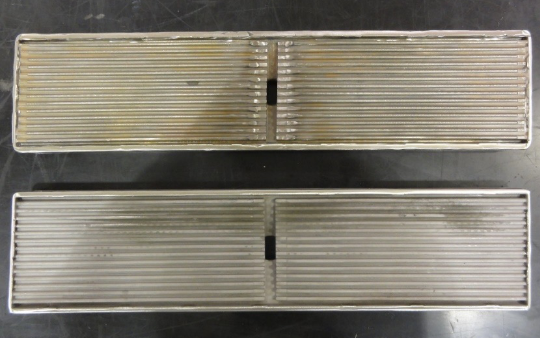

| Dewatering filtration |

Dewatering Centrifugal separator |

Screen Screen |

Squeezing (soymilk, fruit juice) Pharmaceuticals, food products, chemical products |

| Granulation | Extrusion granulator | Screen |

Pharmaceuticals Food |

| Microfiltration |

Strainer Automatic sludge removal equipment |

Screen Basket |

Adhesives, sludge process Beverages Tufftride process of automotive parts |

| Fiber spinning | Glass wool Production equipment | Spinner head | Glass wool |

| Film cooling | Gas turbine | Nozzle, blade |

Gas turbine |

| Air transportation | Floating chute | Plate | Ceramics production |

| Muffling | Low noise valve | Pipe | Boiler for thermal power plant |

| CVD | Semiconductor production system | N2 Shield | Semiconductor |

Hole processing specifications

- Standard hole diameter

- φ0.07~φ1.00(mm)

- Hole diameter accuracy

- ±0.03~0.05(mm)

- Plate thickness

- 0.3~8.0(mm)

- Aspect ratio

- 1:10(hole diameter: plate thickness)

- Hole pitch / Pitch accuracy

- Hole diameter×2 / ±0.05mm

- Hole angle (tilt angle)

- 20°~90°

- Hole layout

- 60° Parallel layout (standard specification) / Reverse 60° layout / 45° Plover layout / Parallel layout

※It can be freely combined within the constraints of material x hole diameter x pitch x plate thickness (x hole layout).

Size of processed goods

- Sheet (screen)

- 1,950x900(mm)

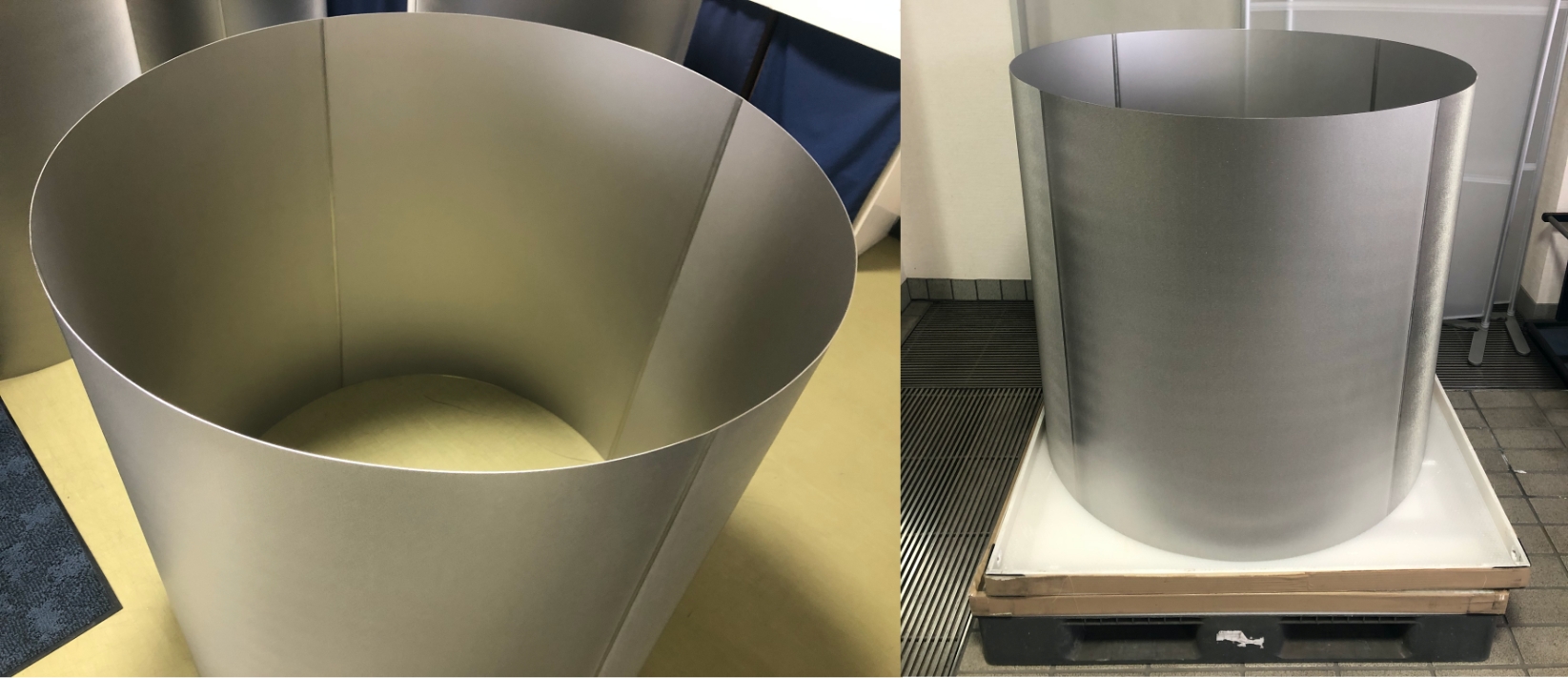

- Molded products (cylindrical shape)

- φ630x900L(mm)

- Molded products (complex shapes)

- φ400(mm)

※The above is the maximum processing size.

※Please consult with us about the sheet (screen) within the limits of the plate thickness and other restrictions.

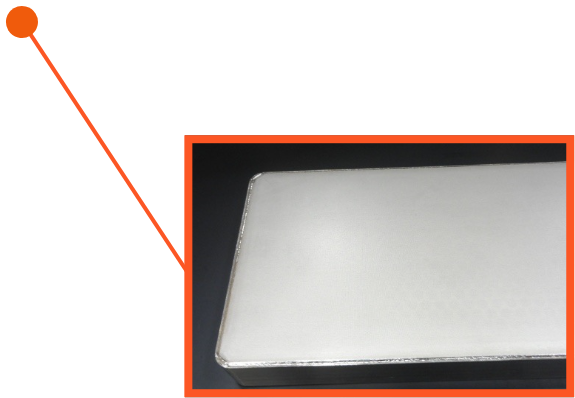

About secondary processing

We are able to design and manufacture products with a high degree of freedom according to the customer’s request by making full use of our material technology, drilling technology, plastic working technology, machining technology, and welding technology.

Molding Example

We have introduced plasma welding, laser welding, and other reliable welding technologies into our products to increase the joint strength. The welded structure also greatly increases the degree of freedom for large products such as φ1,500x900H (φ750×1,950H).

Of course, EBP screens can be freely molded on materials supplied by customers.

Supplied material

Reinforcement material

EBP Screen

Please feel free to contact us.